Friday the 13th, a date that has been associated with bad luck since the beginning of time. Many people believe that this day is cursed and they would tell spooky tales about misfortunes that have taken place on this day. Not to mention that they even make buildings without a 13th floor. Personally, I think 13 is my new lucky number. It has been a memorable Friday the 13th.

I love meeting the best and the brightest in our industry. The misfits, the disruptors, the innovators, those make the best interviewees. They make the best companies in the world.

And 71 years ago, one brave man with a vision started a moving company. The 495 highway wasn’t yet built at that time. What was one man and a van back in the 1947, has grown into a leading global moving business – the Paxton Companies. It couldn’t be just luck.

Now I had the honor to meet Bill Paxton, a third generation Paxton, who is the COO and Treasurer at the Paxton Companies and run the business with his brothers. It’s some time around 11 am and here I am at the core where all the magic happens. It is a huge, like a huge-huge facility where you can easily see that negligence is not acceptable here and everything is at the right place. After a tour of the facility here in Springfield, VA, we head to Bill’s office where we start the interview.

With Bill Paxton, COO and Treasurer at the Paxton Companies.

Manuela: Hi Bill, I am very glad that you decided to share your story with our readers. Let’s start with the history of the Paxton Companies. Can you tell us a bit more about your business?

Bill Paxton: Albert Lee Paxton founded the company when he got back from World War 2 in 1947. He started with one truck and his storage unit in his house. And obviously, the company has grown to where we are today. We currently have three warehouses in the DC Metro area – the logistics warehouse in Alexandria, VA, this is our operations warehouse here in Springfield, VA and the long-term storage warehouse in Manassas, VA. And that is our largest facility.

We have 275 employees and we have physical offices and warehouses in Iraq, Afghanistan, and transshipping offices in Singapore and London.

Now the company is run by the third generation. My brother Freddy is our Chief Marketing Officer, I am the COO and Treasurer, and my younger brother Chris is in our long distance operations department. Plus, we have other family members in the business. Uncle David and his wife run a record storage company and their kids would help in the summers. My cousin John is our CFO. My cousin Mary Kathleen is our Quality Customer Service Manager. If I leave a family member, I will get in trouble, but I think that is all the family members.

Manuela: 70 years in business is quite a milestone. What are some of the most significant awards that you have accomplished so far?

Bill Paxton: Wow. Significant awards. Well Move for Hunger‘s “Mover of the year” is one of the most amazing awards we have been awarded so far. Adam and his team have done such a great job helping us help people. It is a very easy thing to do and everyone should do it. Actually my wife and I ran a half marathon and raised $6000 for Move for Hunger. It was an awesome experience. We rescued 12,000 lbs. of food from the marathon. I think that equals to 10,000 meals, which is spectacular. It is a huge impact.

We are affiliated with Atlas Van Lines and we have been a top agent for a couple of decades. We won “Family Business of the Year” award last year.

Also, we are an ISO-certified company. We have the ISO 9001 Quality Management certification for over 15 years.

And in addition to that we have the ISO 140001 Environmental Management certification. We were the first moving company in the country to get the ISO 140001 designation. We have that for more than a decade.

Some of the milestones the Paxton Companies has reached so far.

This is a way to regulate our quality, and with the environmental standard, we try to lessen our impact on the environment through recycling and other initiatives. For example all of our crews are 95% paperless – they use IPad and electronic inventories.

We started doing virtual surveys, it is interesting that some of our customers even require it. Most of our younger customers really like it. They don’t want to have someone in their home do the estimate. I think it is just a matter of time before everybody starts doing it. We have 4 people in our office who do just video surveys at this time. It’s good for the business and it’s good for the environment. It’s clean and easy.

Last but not least, our drivers have been awarded to be ones of the safest in the industry by both AMSA and Atlas Van Lines.

Manuela: How do you ensure that your customer service is state of the art?

Here are the names of all loyal employees who have been charged with The James “Beep” Horne Distinguished Service Award.

Bill Paxton: Well, one of the core principles in our company is to treat our employees like family. And if you have well trained and happy employees, the customers will benefit from that.

We focus on our employees. We spend a lot of time and effort to make sure that our techniques and training are the latest and the greatest. A couple of years ago we flew one of our operation gurus, Luis, to LACMA conference in order to see how people in other countries do things. And he brought back some really nice ideas and we integrated them into our current processes.

Manuela: And what were those?

Bill Paxton: He made some great tutorials on how to handle fragile items in ways that we haven’t done and some other non-standard techniques. Loading a truck is loading a truck, but how you pack and put items in the boxes can make a difference.

Manuela: What kind of technology do you use in your business processes?

Bill Paxton: Along with the electronic inventories, all of our documentation is digital as well. We use digital agreements that are electronically available to all customers. A lot of our customers don’t interface with paper at all. We will send the documents over email.

However, the military still requires paper forms. Hopefully, they will convert to digital as well. They will get there. The U.S. Government and the U.S. Military are the largest customer in our industry.

Manuela: What are some of the toughest regulations that you have to comply with?

Bill Paxton: Obviously, there is a lot of regulation in what we do.

The HOS rule that applies to drivers is a tough one. It impacts their ability to earn living.

And there are other regulations which I think are more geared towards the freight industry and the general commodity business, rather than household goods.

AMSA is doing great job lobbying and trying to get the legislators to see how we are different and get exemptions in some of these rules. We all have the same goal here – to get our customers’ goods from point A to point B, as quickly, safely and as efficiently as possible. We want our drivers to be safe.

Manuela: You said that the government is the largest customer. What are some other challenging jobs that you have ever done?

Bill Paxton: Yes, we are located in a very strategic place and we have had a lot of interesting clients. We have moved aircraft and bulletproof vehicles for private clients.

This is a small part of the Paxton’s fleet.

We moved a very special item for the Library of Congress. One of the most interesting of its archives can be found in the American Folklife Center. It includes nearly half a million hours of sound recordings. The center was created in 1976 to collect and preserve creative expressions of people from diverse communities. Its roots can be traced back to a 1928 “national project” to collect the entire body of American folk music. Actually, the hit movie Songcatcher was loosely based on the work of these very historians.

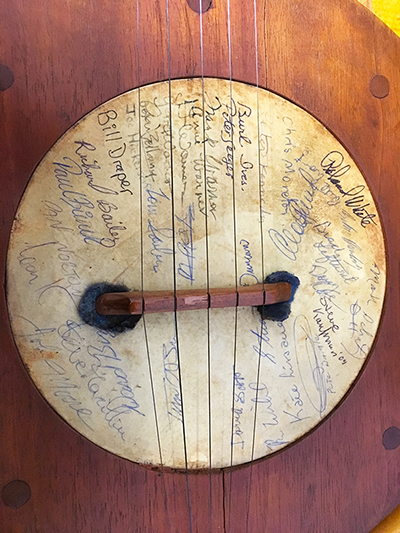

The American Folklife Center’s collection now includes a hand carved, five string banjo that is made from an eastern black walnut tree. The instrument was hand crafted by North Carolinian Frank Proffitt Sr., a veritable folk hero from Appalachia. Frank was a carpenter and luthier by trade and probably best known for the song “Tom Dooley”.

The experts at Paxton eagerly managed the logistics required to safely transport this national treasure from the home of its donor in the UK to its final destination in Washington, D.C. Moving delicate instruments, especially something of this nature, which is truly one of a kind, can be really nerve racking. The entire Paxton team worked together to securely pack the three foot long banjo in a custom built crate before shipping the mere 13 pounds of precious cargo to D.C.

We are always excited when one of our moves also has a positive effect on the environment in the communities we work. We were delighted to transport the equipment used to study the endangered snow leopard in the remote Hindu Kush Mountains. Afghanistan is home to a population of the endangered and elusive snow leopards. The species is under a constant threat from poachers and farmers who fear the leopards are attacking their livestock. In order for experts to protect them, they needed to do more research. This shipment required Paxton International staff to navigate complex processes governing the importation of special veterinary and film equipment vital to the client’s project. Once delivered to our client in Afghanistan, the equipment provided the first ever satellite tracking of snow leopards. And that enabled scientists to learn more about these creatures in order to find better ways to protect them.

This is a five string banjo made from an eastern black walnut tree. It was hand crafted by North Carolinian Frank Proffitt Sr.

Next, there was this move where the client’s house was less like a home and more like a museum. He had traveled the world collecting rare and priceless items along his journey. And his wife was a well versed coffee connoisseur who insisted on sitting down to a long coffee break with the entire Paxton Team each morning before work could begin. Then, after roughly two hours of work, the client (who was a chef in his spare time) insisted on an elaborate and delicious 3-course lunch for the whole team where he would tell the stories behind the fantastical items he had acquired.

This client had over 1,000 silver spoons and could tell you the exact story behind each one. After lunch it was then time for a nap! The pair insisted that everyone in the house relax in their own bedrooms and take a nap before work could resume. No matter how much the team insisted the work be done more quickly, the clients insisting on the lengthy coffee breaks, the extravagant lunches and refreshing naps. This was the daily routine for the week it took to pack the client’s 3,000 square foot home. The value of their goods was well into the millions. In the end, nearly the entire house was packed in custom crates and required two full 40’ containers, a full 20’ container, and several additional lift vans.

And even a move from here (Springfield, VA) to Fairfax, VA can be challenging. What we do is to train and prepare ourselves and so the challenging is not as challenging, it is more like fun.

Everyone who works here, works here for a reason. And they enjoy coming to work because of the challenging situations. They try to do things right for the customer. For example – we can be moving a two-income family – mom has found a new job at a new location and dad has to stay with the kids until they can relocate. It is very hard for them. Our job would be to make their life as simple and easy as possible. We even partner with third-party companies, like relocation management companies and if one of our clients requires an additional service like finding a new home, we will bring in an expert to the move process.

Relocation is not easy, especially when the reasons behind the move are negative.

Manuela: Speaking about customer service, what is your experience with reviews?

Bill Paxton: Online reviews are a double-edge sword. There are two sides of every story. I actually don’t mind online reviews, because it gives the customer another way to send their feedback and communicate with us. I love being able to talk with somebody about what went wrong in one of their moves, because that gives us the opportunity to become better. On the other hand, sometimes it is very difficult when the customer doesn’t want to cooperate. However, if they get back to us with a particular problem and are willing to listen to us and more importantly, let us fix it, that means everything in the world.

Paxton shipped this sculpture created by internationally recognized artist Joel Shapiro from New York to Guangzhou – China where it was installed outside the US Consulate.

Sometimes reviews are a little bias, but overall we get really good information and feedback from those that help us provide a better service in the future.

Here at Paxton, we have a continual improvement system, which is part of our ISO standard. It is an online system and all of our employees have access to it – there is a form, it is a CIF form, where they can report environmental situation or non-compliance with a safety standard. Any employee can go into the system and alert when something with a move has gone wrong, and the issue will come directly to me and I review the situation. Later during our meeting we will identify the exact issue.

Let’s say we are seeing a situation where we systemic situation where we scratch floors. One of our customer service representatives report that we have scratched like 5 floors this month. That would be a CIF. Then we look for possible resolution. It may be our supplier that we buy protective materials from who hasn’t met the highest quality standard or it might as well be something in the process that we are missing.

Another good thing about this procedure is that the employee who has submitted the CIF will receive an email and will be aware of all steps taken until the case is closed. This way employees feel engaged, they feel part of the company.

Manuela: What are some great ways to let employees know that their work and opinions are valued?

Bill Paxton: I sit down with every single person that we hire and we go through a checklist. Then when an employee first meets with their manager, the later will go through all employee expectations like what time the employee goes to work and all other job responsibilities and duties.

Some of our employees start working at 6 am and work until 3 pm, other would do 8 to 5 pm. We are flexible, because we want our employees to be happy in life and not just at work. We have a lot of working mom and dads.

Paxton employees participate in a bake sale to support FIDI’s charity – Operation Smile, which makes a tangible difference in the lives of children in poverty-stricken communities.

Actually employees go first to human resources where they go over all of our policies, like the non-smoking one. We also have zero tolerance policy for sexual harassment. Everyone goes through background checks and drug testing before they come to work for us.

Manuela: What are some other examples of how Paxton takes care for its people?

Bill Paxton: We have this event on May the 1st when we all gather together. In the summer, we do cookouts and barbeques. Every year we have a “field day” where we have competitions between our departments and employees. This year we are also planning to have a taco truck. We try to create a friendly environment where people can hang out together. This way employees can interact with their colleagues from other teams who they don’t get to see on a daily basis.

We do engagement surveys with our employees. For example, my brother Freddy would sit for hours in our conference room and he would talk with any employee about their job and we can make things better for them and for our customers.

I have an open door policy and so any of our employees can come in any time of the day and I will stop whatever I am doing if they have an issue. I am always available to help.

Sometimes it could be something real simple. See, we have two entrances here and I used to come in from one entrance every day. I am one of the first people to come in the morning. And so I walk through the door and I say “hi” to all the employees sitting around that door and then I will go to my office, and start my day. One day, one of our employees who works near the other entrance asked why I wouldn’t ever greet them. I had no idea I was doing it. And so, now, one day I would come from the one entrance and the other day, from the other entrance.

Having an open door policy, you make your employees feel appreciated and comfortable.

Paxton delivers our troops deployed in areas like Iraq handwritten letters of encouragement from their staff in Washington, D.C.

Everybody wants to be appreciated for what they do at work and it is our job as senior management to make sure that our employees feel valued. Everyone has a voice, still not everybody has the opportunity to express their opinions. We give our people multiple vehicles to express themselves. Downstairs, I have a little “suggestions box” where everybody can submit an anonymous note and every week I would check every one of them.

We have all the normal benefits – full health care, paid time off, etc.

Manuela: What are some the mistakes you have made so far and how did you make things better?

Bill Paxton: [Laughs] They might be too many. Well, one of the biggest mistakes that we have made in the past and that we are correcting now is trying to be all things to all people. Some customers are not the right customers for us. Some people are not the right people to work here. Sometimes you try to fit a square peg in a round hole.

Manuela: And what are some of the greatest issues that our industry is currently facing up to?

Bill Paxton: Driver retention has been a problem for years now. The opportunity to earn a good living at a driver level is challenging. We as an industry went from a service industry to a commodity. People think of moving very differently today than they did 20 years ago.

Technology is going to help us. More people will want to get into the industry because of technology. If I make it easier for the customer to buy from me and I make it easier for the employees to understand the transaction, everybody is better off. And we are trying to make this through technology.

We are developing a mobile app right now. Our representatives can text through the system instead of making 10 phone calls. Different customers want to communicate via different channels and we want to be flexible with that.

Manuela: What is next down the road for the Paxton Companies?

Bill Paxton: We want to continue grow globally. We love the core business that my grandfather founded this company on, moving people from A to B here in the United Stated. That is the core of what we do and we will never leave that. Nevertheless, we do enjoy the challenge of international relocation, like moving anything from here to Kabul or Doha, or Juba in South Sudan. We love new challenges.